Norsafe Test & Tag

Your Electrical Test & Tag Safety Specialists for Cairns and the Surrounding Regions

Norsafe Electrical Test and Tag offer services as far west as Chillagoe to the Torres Strait Islands.

Our clients range from large construction companies, nursing homes, schools, small offices, tradesmen, clubs and even electricians.

who we are

About Our Company

We specialise in providing a thorough inspection & testing service. Our technicians are trained professionals who will go above & beyond to ensure you receive a non-disruptive service that exceeds your expectations.

Inspection & Testing of Appliances, RCD trip time testing, Automatic retest sheduling, Competitive pricing, After hours service for busy workplaces, Repairs organised with local electricians, 3 Phase inspection and testing, Remote area servicing, We actually CARE about the safety of your staff & your business.

Our awards

CBWC Awards

Master Builders FNQ Awards 2023

NECA Excellence Awards 2023

Electrical Compliance

Keep your business electrically safe in accordance with the Workplace Health and Safety Act.

Re-testing

Schedule

Norsafe sets down a re-testing schedule to suit your business to keep you compliant.

Far North Queensland

We service businesses from as far West as Chillagoe to the Torres Strait Islands.

20 years in business

You can trust Norsafe Test and Tag to get the job done to the highest standards

WHAT we do

All the equipment used by Norsafe are the latest technology in portable appliance testers (PATs) and are professionally serviced and calibrated. Here is some brief information about our services.

Norsafe Electrical Test and Tag offer services as far west as Chillagoe to the Torres Strait Islands. Our clients range from large construction companies, nursing homes, schools, small offices, tradesmen, clubs and even electricians.

RCD Testing

The Residual Current Device (RCD) or safety switch trip time on each power circuit, is tested.

Test & Tag

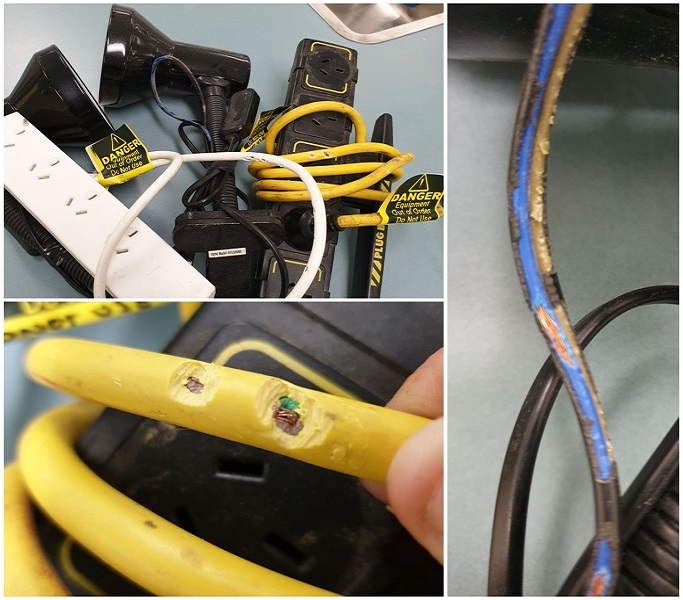

Inspection of leads and appliances for evidence of misuse, or damage from the environment they are located in.

Thermal Imaging

Thermal testing is used to observe the heat that is emitted from objects to make certain that your products can function in any thermal environment.

After Hours Servicing

Our test and tag business offers after hour servicing to accommodate businesses with busy schedules. Our trained technicians are available outside regular business hours to minimize disruptions and ensure safety compliance is achieved.

Electrical Equipment Repair Work

Electrical equipment repair work is a critical aspect of ensuring the safety, functionality, and longevity of various electrical systems and devices.

Remote servicing

Our electrical test and tag business understands the importance of safety in every workplace, regardless of location. That's why we provide our services to remote areas, from Chillagoe to the Torres Straight Island.

Why Choose Us

Locally Owned

High Level of Service

Winner of Various Business Awards

Supports Local Community

Our Clients

Don’t just take our word for it

Commonly Asked Questions

What is Electrical Test and Tag

Electrical test and tag is a safety procedure designed to ensure the safety and compliance of electrical equipment and appliances in various settings, such as workplaces, homes, and public spaces. The process involves inspecting, testing, and labeling electrical equipment to confirm that it is safe to use and meets relevant electrical safety standards and regulations.

Inspection: The process begins with a visual inspection of the electrical equipment. This includes checking for visible damage, loose or exposed wiring, and any other issues that could pose a safety risk.

Electrical Testing: After the visual inspection, electrical equipment is subjected to various electrical tests. The type and scope of testing may vary depending on the equipment’s classification and the applicable regulations. Common tests include earth continuity, insulation resistance, polarity, and leakage current tests.

Tagging: If the equipment passes all inspections and tests, it is tagged with a label that provides essential information, including the date of testing, the next due date for retesting, the testing technician’s details, and any other necessary information to ensure traceability and compliance.

Record Keeping: A record of all tested and tagged equipment is maintained, including details about the equipment, test results, and any required actions. These records are used for tracking, auditing, and compliance purposes.

What are the regulations and standards governing electrical test and tag?

AS/NZS 3760:2022

Australia are primarily governed by AS/NZS 3760:2022, which is the Australian/New Zealand Standard for in-service inspection and testing of electrical 240V, 3 Phase and low voltage equipment.

These standards provide guidelines for the testing and tagging of electrical appliances and equipment to ensure their safety and compliance with electrical regulations. However, it’s important to note that standards and regulations can change, so I recommend checking with the latest local authorities and standards for the most up-to-date information.

Testing Frequency: The frequency of testing and tagging depends on the type of equipment and its usage. Generally, equipment used in harsh environments or heavy usage may require more frequent testing.

Testing Procedures: The standard provides detailed guidelines on the specific tests and inspections that need to be conducted on electrical equipment, including earth continuity, insulation resistance, polarity, and functional tests.

Tagging: Equipment that passes the testing and inspection is labeled with a tag that includes essential information such as the date of testing, next test due date, the testing technician’s details, and any relevant remarks.

Records: Detailed records of all tested and tagged equipment must be maintained. These records help track the testing history of each item and are valuable for auditing and compliance purposes.

Competent Persons: Testing and tagging should be performed by competent persons who have received training and have the necessary knowledge and skills to carry out the procedures. These should be maintained and updated.

Repair or Replacement: If equipment fails testing, it should be removed from service and repaired or replaced, as necessary. The standard provides guidance on the steps to follow in such cases.

Visual Inspection: A visual inspection is the initial step in the process, and equipment showing visible signs of damage or wear and tear may need immediate attention or removal from service.

Why is electrical test and tag important?

It’s essential to perform electrical test and tag procedures to protect the safety of individuals and property, especially in workplaces and public areas where electrical equipment is in regular use. Failure to comply with electrical safety standards can result in legal and safety hazards.

- Prevent electrical accidents and reduce the risk of electric shock, fires, or other electrical hazards.

- Ensure that electrical equipment remains safe and functional throughout its operational life.

- Comply with relevant electrical safety regulations and standards, which can vary by locations

Who should perform electrical test and tag?

The AS/NZS 3760:2022 also stipulates the requirements a person needs to fulfil to be considered a Competent Person – a necessity for someone who wants to Test and Tag.

The Standard states that anybody that acquires the practical and theoretical skills through the following are allowed to test and tag in Australia:

- Training

- Experience on the job

- Qualification

- A combination of the above

This basically means that even if you’re not an electrician, you can certainly still learn to test and tag. The majority of our test and tag students have no electrical knowledge at all and they become a Competent Person from the training course.

How often should electrical equipment be tested and tagged?

What are the costs associated with electrical test and tag?

Contact us today!

We can help you with your electrical compliance needs.

At our test and tag electrical company, we take electrical safety seriously. Our team of highly experienced professionals specialise in testing and tagging electrical equipment to ensure that they meet all safety standards. With our services, you can have the peace of mind in knowing that your equipment is safe to use and in good working condition. We pride ourselves on our efficiency and professionalism, and our commitment to delivering quality service that is tailored to the needs of our clients. Contact us today to learn more about our test and tag services, and how we can help ensure the safety of your workplace.